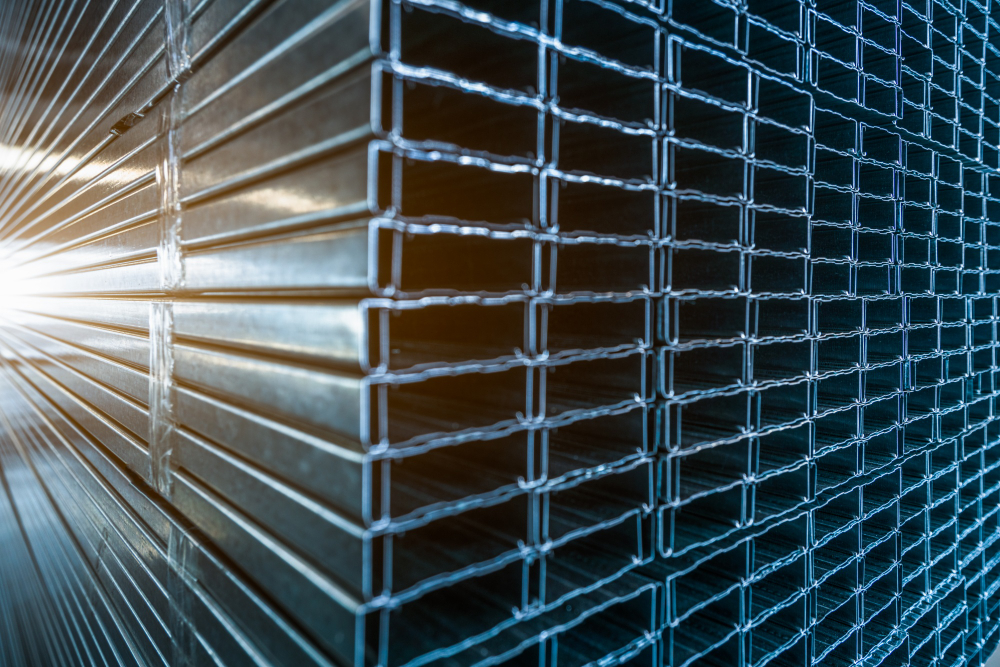

Iron and Steel

Iron, primarily used in the construction industry, is widely applied in curtain and retaining walls, water structures, prefabricated building elements, metro, and tunnel construction. We offer tailored solutions based on demand, providing products to small and medium-sized enterprises with door-to-door or port delivery options.

Billet Iron

Wire Rod

Construction Steel (Rebar)

Steel billets are heated in annealing furnaces and processed through rolling mills to produce reinforcement bars (rebar) in various diameters, ranging from 8 mm to 60 mm. If necessary, heat treatment is applied to enhance mechanical properties. The final product undergoes length cutting processes according to customer specifications and industry standards.

All finished products are subjected to chemical and physical testing to ensure quality compliance. Once approved by the Quality Control Department, they are packaged, labeled, and prepared for shipment according to customer requirements.